Sollich 800 mm Triple Layer Conbar Line with Sollich 1300 mm Enrobing Line

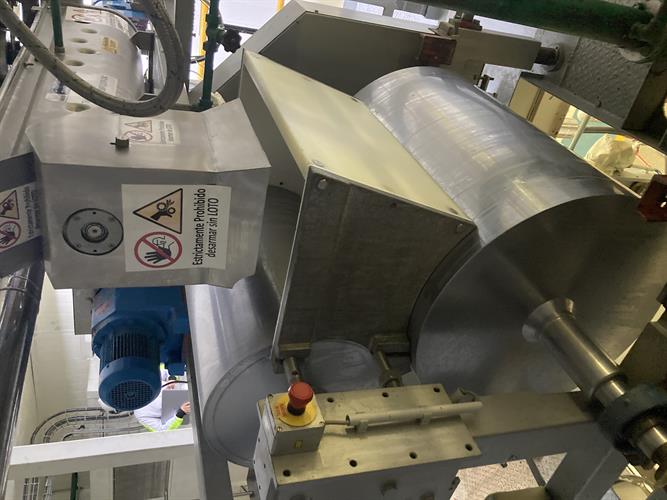

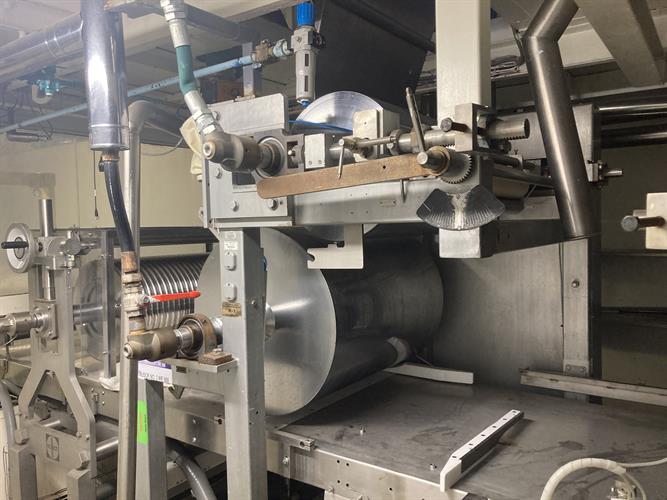

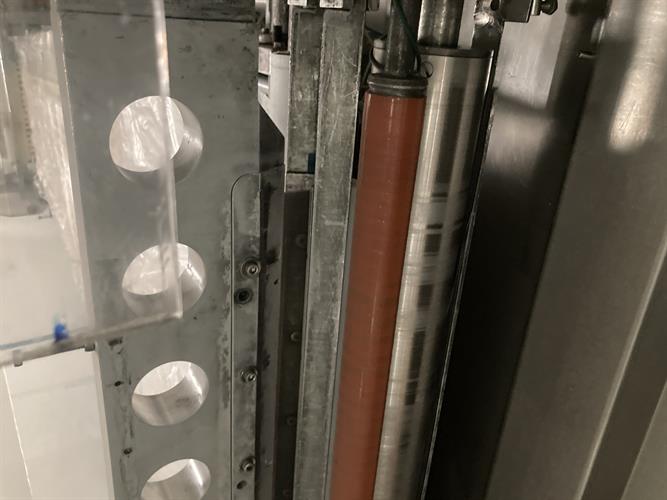

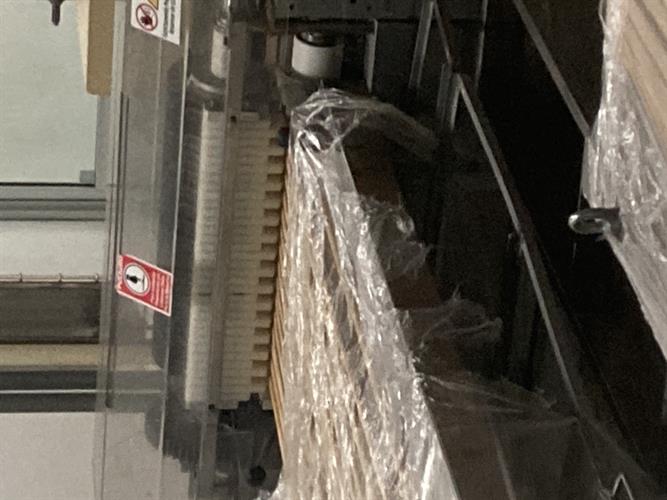

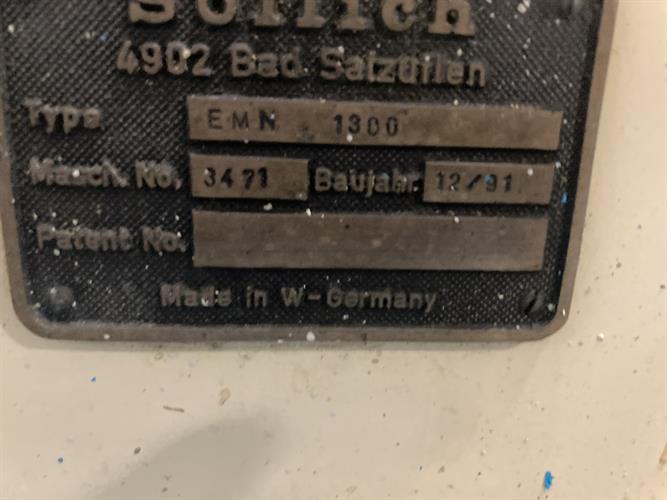

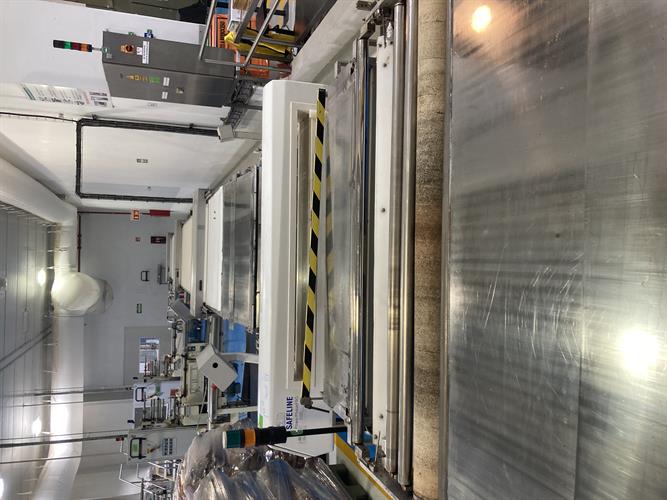

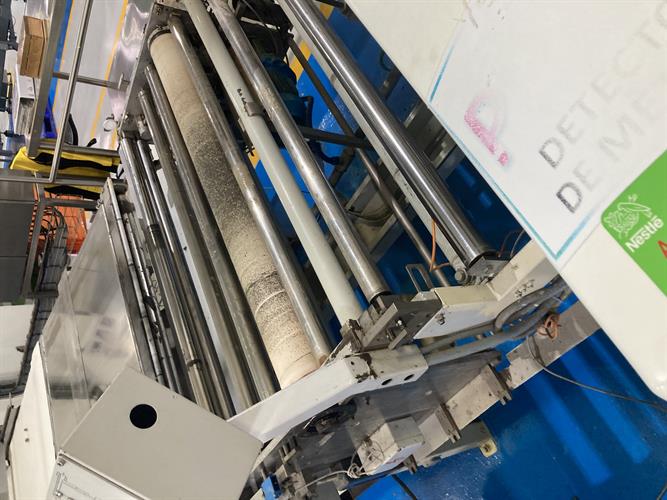

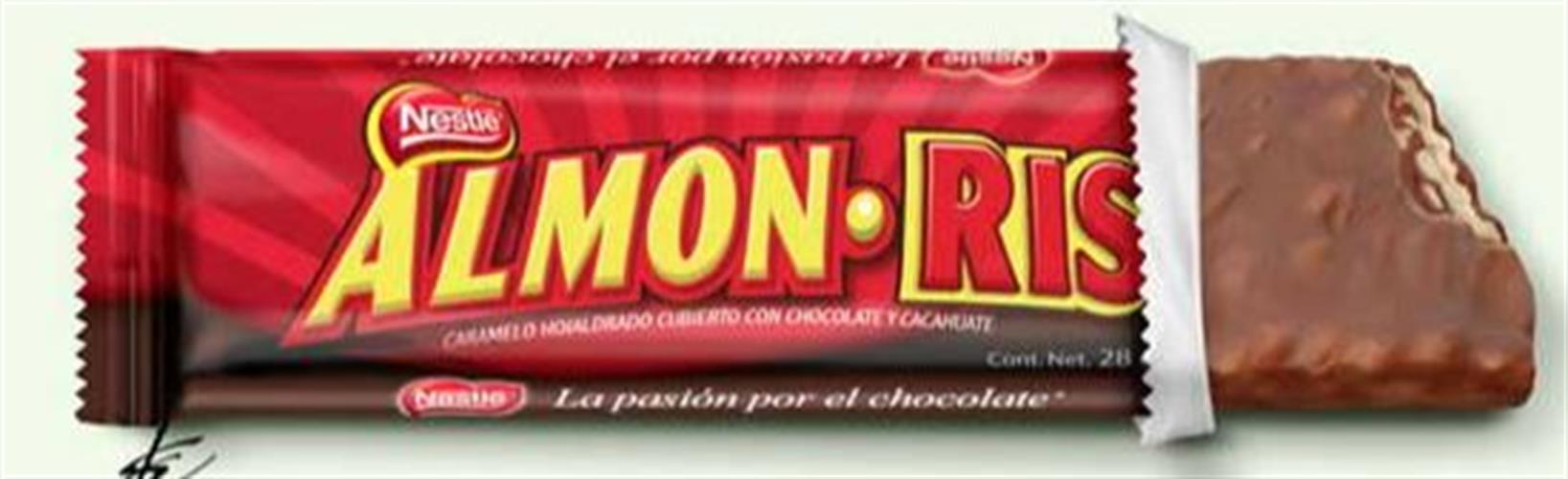

Sollich 800 mm Triple Layer Conbar Line with Sollich 1300 mm Enrobing Line Line was used to produce Nestle Almon-Ris Sollich WE 800 Double Drum Conbar Former - Sollich Contimix jacketed mixer feeding the hopper - Upper jacketed roller 670 mm wide x 480 mm diameter - Lower jacketed roller 820 mm wide x 670 mm diameter - Small dent on top roller - Machine was mounted on mezzanine that fed another Sollich We 820 below it Sollich WE 800 Double Drum Conbar Former - Upper jacketed roller 670 mm wide x 480 mm diameter - Lower jacketed roller 820 mm wide x 670 mm diameter - Serial#518 built 1991 Sollich WE 800 Double Drum Conbar Former - Upper jacketed roller 670 mm wide x 480 mm diameter - Lower jacketed roller 820 mm wide x 670 mm diameter Sollich Profiling Roller - 750 mm wide x 460 mm diameter - (25) 30 mm grooves Sollich Glycol Chiller Sollich plate type Tempering Unit (no tag) Sollich 820 mm wide x 30-meter long Cooling Tunnel - Jacketed bed - Cold air circulation - Belt drive - Tracker Sollich Slitter, Spreader and Guillotine Cutter - Slitter with (34) cutting blades - Spreader belt conveyor (spare spreader belt conveyor included) - Guillotine Cutter 1500 mm wide, mechanical type Sollich EMN 1300 Enromat Enrober - Jacketed tank with circulating pump - Flow pan - Blower - Serial#3469 built 1991 Sollich 1300 mm wide x 15-meter long Cooling Tunnel - Jacketed bed - Cold air circulation - Belt drive - Tracker Sollich EMN 1300 Enromat Enrober - Jacketed tank with circulating pump - Flow pan - Blower - Serial#3471 built 1991 Wire mesh belt conveyor used to place nuts on top of enrobed products. Nut feeder is not included. Wire mesh belt allows loose nots to fall through the belt. Sollich 1300 mm wide x approx. 30-meter long Cooling Tunnel - Jacketed bed - Cold air circulation - Belt drive - Tracker Safeline Metal Detector - Mounted on discharge conveyor after final cooling tunnel Smart belt system to Feed (3) Sig SB Flow Wrappers (flow wrappers not included) The line has been dismantled and now is in a warehouse in Toluca, Mexico S:\Users\jsgreenb\Nestle Mex

This product is no longer available.